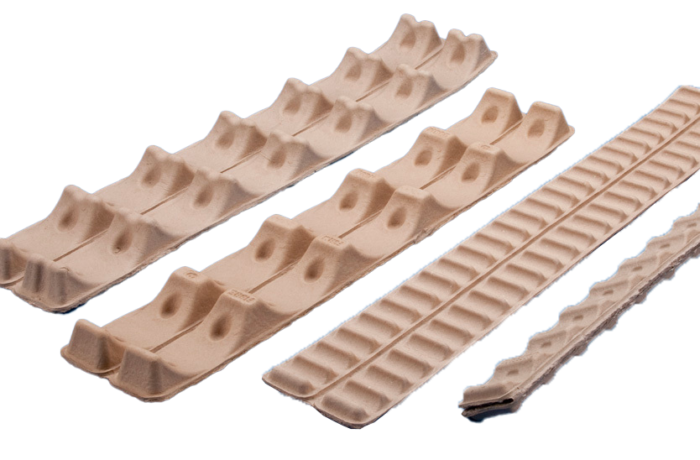

Molded Pulp Roll Cradles: Eco-Friendly Packaging Solutions

Introduction:

In today's world, where sustainability and environmental consciousness are of utmost importance, the need for eco-friendly packaging solutions has become increasingly evident. One such solution gaining popularity is the use of molded pulp roll cradles. These cradles, made from recycled paper fibers, offer numerous advantages over traditional packaging materials, making them an ideal choice for protecting delicate items during transport. This page explores the concept of molded pulp roll cradles, highlighting their environmental benefits, protective qualities, and potential applications.

Environmental Benefits:

Molded pulp roll cradles are highly regarded for their environmental benefits. They are predominantly made from recycled paper fibers, making them a sustainable alternative to non-recyclable materials such as plastics or foam. By utilizing recycled materials, these cradles help reduce the strain on natural resources and minimize waste. Moreover, their biodegradability ensures they can be easily composted or recycled at the end of their lifespan, contributing to a circular economy and reducing the burden on landfills.

Protective Qualities:

One of the key advantages of molded pulp roll cradles is their exceptional protective qualities. The cradles are designed to provide a cushioning effect, effectively absorbing shocks and vibrations during transit. This is particularly crucial when transporting fragile items, such as glassware, ceramics, or electronic components. The fibrous structure of the molded pulp provides a natural shock-absorbing barrier, reducing the risk of damage or breakage. The cradles can be custom-designed to fit the specific dimensions of the product, ensuring a snug and secure fit that prevents movement and minimizes the potential for impact-related incidents.

Applications:

Molded pulp roll cradles find applications across various industries due to their versatility. They are commonly used in the electronics industry for securing and protecting delicate electronic components, such as circuit boards or sensors. The automotive industry also benefits from these cradles by using them to transport fragile car parts securely. Additionally, the food and beverage industry utilizes molded pulp cradles for packaging glass bottles, providing both protection and an eco-friendly image for their products.

Innovation and Design:

The manufacturing process of molded pulp roll cradles involves a combination of advanced technology and innovative design. The raw material, recycled paper fibers, is mixed with water to form a slurry. This slurry is then poured into molds, where it is shaped and dried to create the final product. The flexibility of this manufacturing process allows for customization and ensures that cradles can be tailored to meet specific product requirements.

Conclusion:

Molded pulp roll cradles offer a sustainable and effective solution for protecting delicate items during transportation. With their eco-friendly nature, exceptional protective qualities, and diverse applications, they have emerged as a preferred choice for many industries. As the world continues to prioritize sustainability, these cradles present an ideal alternative to traditional packaging materials, reducing environmental impact and promoting a more circular economy. By embracing molded pulp roll cradles, we take a significant step toward a greener future in packaging and shipping practices.