Molded Paper Pulp Trays Benefits

Paper pulp is the raw material used for making products and paper-like molded paper pulp trays. The material includes mineral, artificial, or vegetable fibers. Paper has become a vital aspect of day-to-day activities and has been around for a very long time. Most of the papers are made from pulp extracted from wood.

Paper pulp processing

Paper and molded pulp are manufactured from cellulosic fibers and other plant materials. Synthetic materials are at times used to provide the end product with special characteristics. Other papers are created from wood fibers, the residue from bagasse or sugar cane, rags, cotton linters, and flax.

Once it has been used, paper is recycled, blended with virgin fibers, and turned into paper again. It’s later used for packaging products like films and explosives since they require packaging created from cellulose like rayon, cellulose acetate, and cellulose esters.

The reason behind the pulping process is to get rid of lignin without affecting the quality of the fiber. The process also frees the fibers by getting rid of any impurities. This helps avoid any disintegration or discoloration of the paper in the future.

Every pulp-producing process produces its own kind of paper products. However, different pulps are mixed like a recipe to develop products containing specific properties. For example, more significant amounts of bleached Kraft pulp with lesser amounts of recovered and mechanical paper pulp are used to make high-quality writing and print grade papers like magazine and copy papers.

Types of Products made from pulp?

Pulp is the base of a good number of paper products. The packaging of your medicine and cereal, paper towels in the kitchen, and paper that the grocery ad is printed on all begin as wood pulp.

Fluff pulp is used in personal care and absorbent products such as feminine hygiene, adult incontinence, and diapers. Pulp solvent can be spun into textile fibers such as Lyocell or rayon, used as thickeners for other items, or reacted chemically to create films or fibers.

Below are the three benefits of molded paper pulp trays;

-

Molded paper pulp trays are sustainable

The potential for sustainable growth for companies across all industries has been underscored by the manufacturer of molded paper pulp packaging. This kind of packaging material is suitable for cushioning items, especially during transportation, since it’s built from recycled newsprint or paperboard.

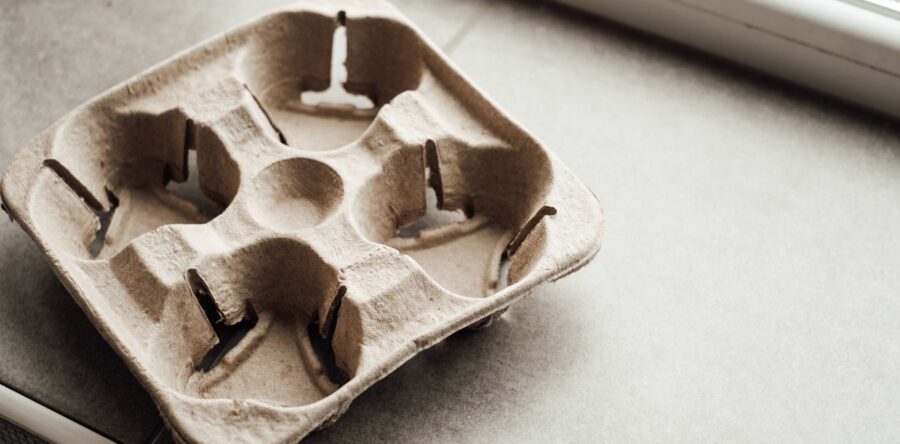

In recent times, molded fiber is used globally for packaging purposes, like food trays, drink holders, and other non-edible products. With the concern for environmental pollution becoming more and more crucial by the day, replacing non-compostable and non-biodegradable products with more environmentally friendly options is almost becoming a necessity across the business world.

Molded paper pulp trays are not only economical, but they're also becoming a suitable option compared to petroleum-based materials, plastics, and Styrofoam. Certain stability comes with molded paper pulp as far as prices are concerned, making the material even more reliable. The packaging requires even less capital to be implemented.

To make it even better, the material can be made waterproof by adding a layer of wax. This enables the molded paper pulp to stay intact even when in contact with water during travel. The package may soak and fall apart if in contact with water because it's made from wet pressing paper-based material.

-

Molded paper pulp is compostable

Molded fiber is eco-friendly and economical throughout the manufacturing process. They are also compostable and biodegradable, which reduces waste at the end of the day. The environment would smile back at humanity if the molded fiber were to replace plastic not only as a compostable packaging solution but in every possible way.

-

They are customizable

Molded fiber pulp trays can easily be customized when it comes to their design, color and also put some logos on them for branding. They also can’t be left behind by other materials when it comes to providing protection and cushioning to products.

A good number of consumers have confessed to feeling safer with their products being packaged in molded fiber trays compared to thermopile or plastic packaging materials.